Exploring the Versatility of Blow Molding Machines in Modern Manufacturing

Blow molding machines have revolutionized modern manufacturing by enabling the production of lightweight and durable plastic products. These machines are instrumental in crafting a wide range of items, from simple bottles to intricate custom parts required by diverse industries. Their ability to produce hollow shapes swiftly and efficiently underscores their significance in today's manufacturing ecosystem.

The versatility of blow molding machines is evident in their applications across various sectors. They are crucial in manufacturing containers and bottles for the food and beverage industry, as well as custom parts for automotive and consumer goods. This adaptability extends to the production of complex shapes, allowing tailor-made solutions for unique design needs. From automotive components like fluid reservoirs to cosmetic bottles, the machines showcase their capacity to meet different sector demands.

Moreover, blow molding technology is particularly adept at producing complex shapes, highlighting its adaptability in various manufacturing processes. Its capability to mold products with intricate designs while maintaining efficiency and cost-effectiveness makes blow molding an invaluable asset in industries like packaging, automotive, and consumer goods. This technological adaptability ensures that blow molding remains at the forefront of innovative manufacturing solutions, meeting the evolving needs of modern society.

## Exploring Different Types of Blow Molding Machines### Extrusion Blow Molding Machines

Extrusion blow molding machines are renowned for their ability to produce hollow plastic products with high efficiency, ideal for large-scale manufacturing. This process involves the continuous extrusion of a molten plastic tube, known as a parison, which is then enclosed in a mold and inflated to form the desired shape. This technology is particularly useful for creating bottles, containers, and automotive parts due to its ability to produce complex shapes with handles and variations. Its capacity to handle various materials such as HDPE, PP, and PVC makes it a versatile choice for manufacturers aiming to optimize production.

### Injection Blow Molding Machines

Injection blow molding combines the injection molding and blow molding processes, creating products with high precision and complex designs. The initial stage involves injecting plastic into a preform mold, which is then transferred to a blow mold for inflation. This method is praised for its ability to produce pharmaceutical bottles and jars with exceptional accuracy, offering significant design flexibility and achieving uniform wall thickness. For industries where precision and clarity are vital, such as pharmaceuticals and cosmetics, injection blow molding machines provide an excellent solution.

### Stretch Blow Molding Machines

Stretch blow molding machines are designed for producing lightweight, high-strength containers primarily made from PET material. During the process, the preform undergoes a stretching phase to enhance its clarity and strength, making these machines perfect for manufacturing beverage bottles and food containers. These machines are highly valued for their ability to produce containers with excellent clarity and robustness, which are essential for maintaining product quality and consumer appeal. The stretch blow molding process ensures high-speed production and is suitable for anyone needing thin-walled, lightweight packaging solutions.

## Innovative Products in Blow Molding Technology### 5 Gallon PET Preform Plastic Injection Molding Machine

The 5 Gallon PET Preform Plastic Injection Molding Machine plays a crucial role in high-volume production. It significantly reduces waste during manufacturing processes due to its efficient design. This machine is pivotal in creating heavy-duty containers that maintain consistent quality and performance. With its modular design and advanced injection systems, it ensures stable and accurate production, making it a reliable choice for large-scale manufacturers.

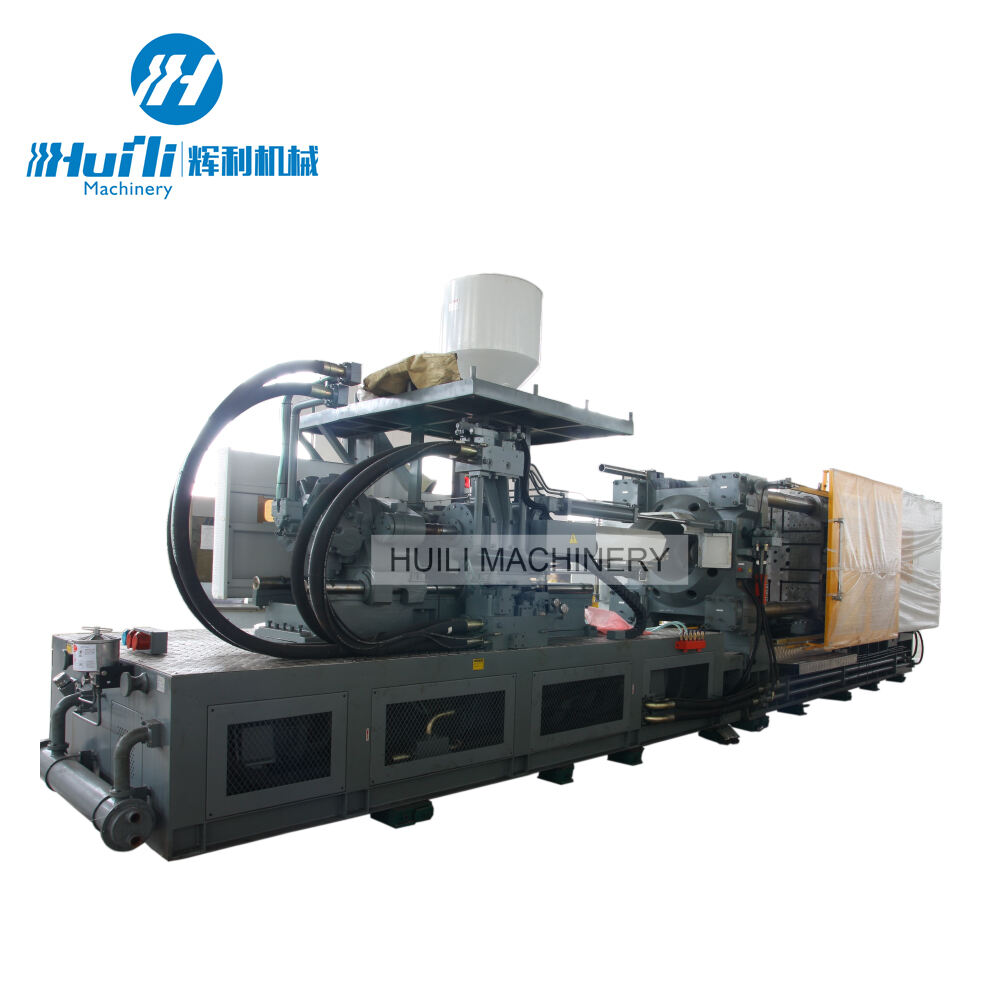

### 650 Ton Injection Molding Machine for Plastic Crate Container Box Making

The 650 Ton Injection Molding Machine is a standout for high-capacity production, adept at manufacturing robust containers essential in logistics and storage industries. This machine's high tonnage capability ensures a fast turnaround for large orders, thereby enhancing manufacturing efficiency. With its precision design, it is adept at producing durable products that can withstand the rigors of transportation and use.

### Advanced Technology Small Products Plastic Injection Molding Machine

Designed for precision, the Advanced Technology Small Products Plastic Injection Molding Machine is tailor-made for producing small, intricate plastic components. Its automated features optimize production cycles, significantly reducing operational costs while maintaining high-quality output. This machine's engineering excellence enables manufacturers to meet the demand for detailed and high-precision pieces for various applications.

### Automatic Plastic Bathtub Making Injection Molding Machine

Catering to large-scale production, the Automatic Plastic Bathtub Making Injection Molding Machine utilizes advanced molding technology to enhance efficiency and ensure quality control. It accommodates various shapes and sizes, making it suitable for diverse market needs. This machine's automated processes streamline production, providing a consistent output while accommodating intricate designs and features that modern consumers demand.

## Advantages of Using Blow Molding MachinesBlow molding machines are renowned for their cost-effectiveness, particularly in high-volume production scenarios. This manufacturing process benefits from economies of scale, allowing businesses to produce massive quantities at reduced costs per unit. Its efficiency is unmatched when producing items like plastic bottles or automotive parts, which require swift and large-scale production capabilities. As businesses strive for competitive pricing, the economic advantages offered by blow molding provide a significant edge.

Precision in manufacturing is another advantage of blow molding machines, ensuring consistent quality throughout the production process. By utilizing advanced molds and controlled parameters, defects are minimized, and waste is substantially reduced. This consistency is vital for production lines, especially when dealing with intricate designs or demanding specifications. The result is high-quality products that meet industry standards, supported by a process that assures reliability and uniformity.

Additionally, these machines are designed for energy efficiency, contributing to operational cost savings and reduced carbon footprint. Blow molding technologies incorporate energy-saving components and optimized cycles, resulting in lower electricity consumption. This not only translates to reduced operational costs but also aligns with the growing demand for sustainable manufacturing practices. As companies become more environmentally conscious, leveraging machines that decrease energy use can significantly enhance a brand's sustainability profile.

## Future Trends in Blow Molding TechnologyThe future of blow molding technology is poised for transformation with the integration of automation and artificial intelligence (AI). These innovations are set to make operations smarter and more efficient by allowing for real-time adjustments and predictive maintenance. The use of AI enables machines to optimize production processes, reduce manual intervention, and improve precision, leading to enhanced productivity and reduced costs.

Developments in eco-friendly materials are also becoming a critical focus within these future trends. This shift is driven by consumer demand for sustainable products and regulatory pressures for environmentally friendly manufacturing practices. Companies are exploring biodegradable and recyclable materials that can be efficiently molded, ensuring that their processes contribute positively to global sustainability goals.

Finally, enhancing production speed and efficiency through innovative technologies remains essential for maintaining competitiveness in the manufacturing sector. Companies investing in state-of-the-art blow molding machines that leverage the latest technological advancements can expect reduced cycle times and improved product quality. These innovations not only enhance manufacturing capabilities but also align with the industry's growing emphasis on productivity and sustainability, promising a promising future for blow molding technology.